Understanding Wood

When selecting your floor, it is always important to understand the base, the actual material the floor is created from which will affect the appearance. There is more to just the species, there is also the grade and cut of the flooring.

Wood Grades

Clear

A mostly heartwood flooring product that allows all the natural heartwood color variations with minimal character marks and limited color variation. This combination features the infinitely variable grain patterns with the minimal distraction from character marks and color variation.

Select

Contains all the variations in coloration produced by the contrasting differences of heartwood and sapwood. Also included are minimal character marks, such as small knots,

1 Common

A flooring product characterized by prominent color variation that also contains prominent characters (with size limits) such as knots, open checks,

2 Common

Contains sound natural and manufacturing variations including knot holes, open

Character

Character grade hardwood flooring has a natural appearance displaying the full characteristics of the hardwood floor. All color variations occurring naturally in the species are allowed. Small surface knots, cracks, wormholes and mineral streaks, which occur naturally in the forest, help display the wood's natural beauty.

Cuts of Wood

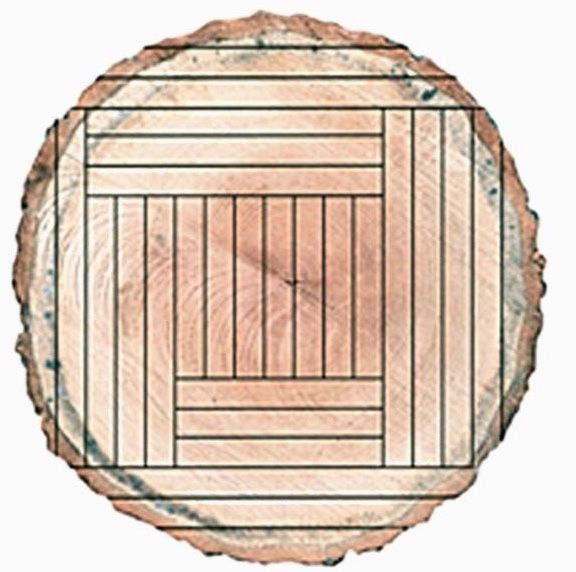

Plain Sawn

is the most popular cut in flooring. Plain-sawn lumber is obtained by making a series of parallel cuts to the log followed by a series of perpendicular cuts to yield the widest width boards. This method produces boards that are wider than

Plain-sawn cuts are made at 0 to 45 degrees and parallel to the tree’s growth rings. Plain-sawn boards tend to shrink and swell widthwise.

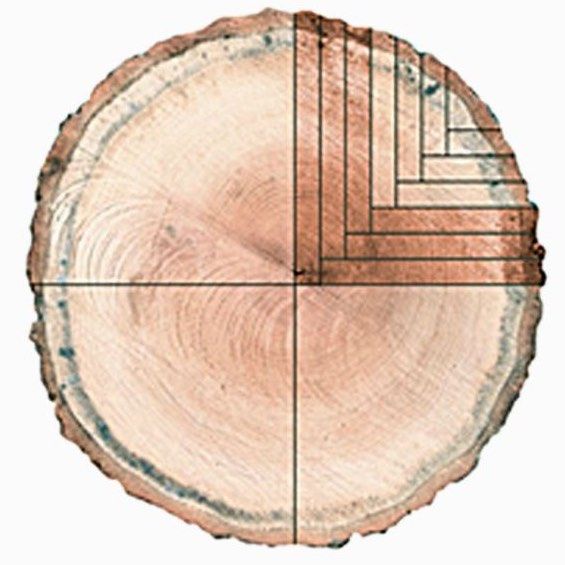

Quarter Sawn

cuts are made at 45 to 90 degrees, creating somewhat narrow boards. Quarter-sawn cuts are made perpendicular to the tree’s growth rings, producing boards with vertical graining and character. It is a more expensive

The quarter-sawn cut of a tree produces more dimensionally stable wood. Shrinking and swelling

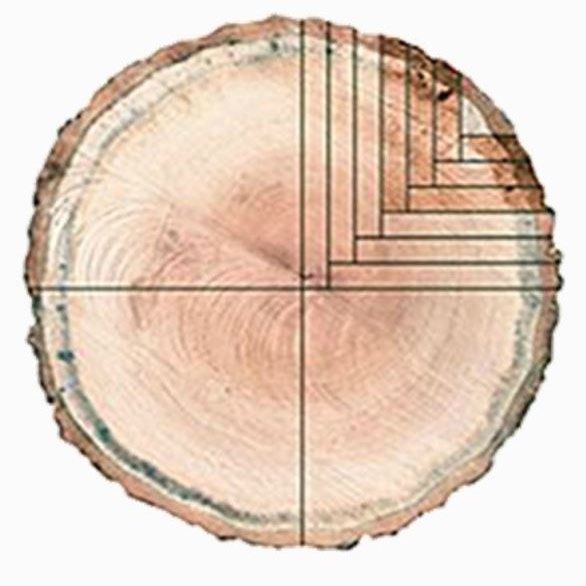

Rifted Sawn

lumber is produced by first quartering the log and then cutting from the center face and working out. The boards that come from the outside edges have 45-degree annual growth rings. These boards come from the smaller part of the quartered wedge of the tree, with the wider boards of the quartered wedge being quarter-sawn. This means rift-sawn boards are narrower than

Rift-sawn cuts are made at 30- to 60-degree angles. They highlight the vertical grain in a tree or, once the floor is installed, the grain that runs lengthwise with the

Live Sawn

wood is cut straight through the log at the center. All remaining cuts are made parallel to the initial cut. This method produces the widest boards, the least waste and combines the characteristics of plain-, quarter- and rift-sawn wood. Live-sawn wood reacts to moisture changes with shrinking or swelling in all directions.